Why Adjustable Weld On Gate Hinges Are Ideal for Heavy-Duty Door Installations

Understanding Weld-On Hinges in Door Installations

What Are Weld-On Hinges and How Do They Work

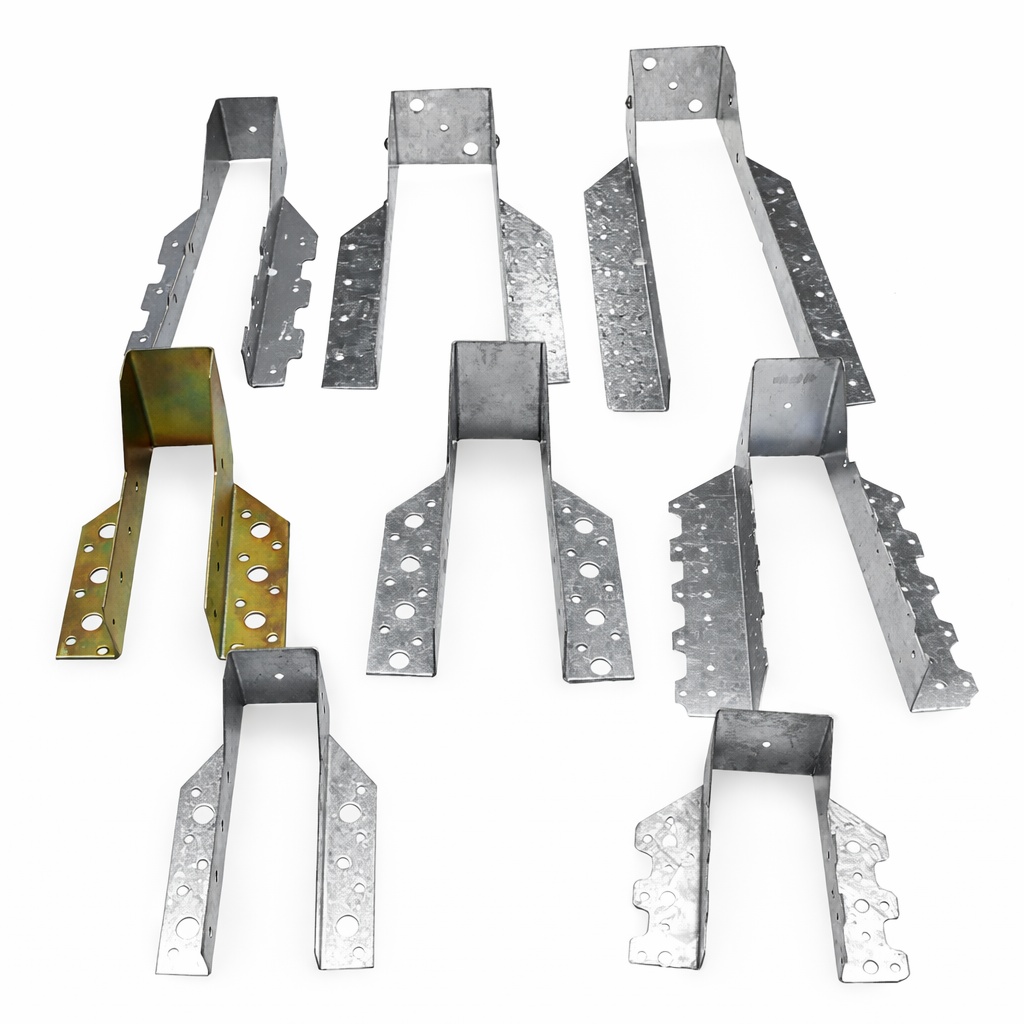

The weld-on hinge functions as a strong mechanical part which designers intend to weld permanently to metal doors and frames. The device contains two parts which weld together for secure attachment while a central pin enables easy rotational movement between them. The design produces a strong hinge point which will endure for many years in door applications that experience high usage and heavy traffic. The product demonstrates excellent strength and reliability which makes it appropriate for use in industrial settings and commercial facilities and security-related environments.

STRZ produces stamped hinges from accurate and reliable steel. These products fit many uses, such as gates, cabinets, and tough doors. The lasting quality of welding makes the hinge a key part of the overall structure. Thus, it avoids any shifting or loosening as time passes.

Advantages of Welding Hinges on Doors

Welding hinges on door brings several key benefits:

-

Deliver a lasting and hard-to-tamper connection, which works great in safe spots like military sites and factory enclosures.

-

Boost the weight it can handle over screw-based hinges, and this matters a lot for big or strengthened doors.

-

Skip the need to drill openings, which keeps the door strong, particularly in thick steel ones where exactness counts.

The Role of Adjustable Weld On Gate Hinges in Heavy-Duty Applications

Key Features of Adjustable Weld On Gate Hinges

Adjustable weld on gate hinges improve basic hinge work by letting you align them after setup. Many of these types have threaded rods or slots for holes, so you can make side-to-side and up-down changes without welding again. This option comes in handy at the end of fitting, when you need exact positioning for gates or doors.

STRZ builds adjustable weld-on gate hinges from thick steel and applies durable finishes like hot-dip galvanization, ensuring long-lasting performance and rust resistance.

Benefits of Using Adjustable Weld On Gate Hinges for Heavy Doors

Enhanced Load Capacity and Structural Support

These hinges use forged steel or strong materials to hold up large gates or doors. They handle the weight and daily stress from industrial gates, barn doors, and business enclosures without trouble.

Long-Term Durability in Harsh Environments

Adjustable weld on gate hinges stand up to rust, decay, and damage in tough spots. Therefore, these hinges fit outdoor jobs well, from sea docks and farm buildings to places near the ocean.

Simplified Installation and Maintenance

One standout aspect of these adjustable types is the simple way to align them after welding, without needing to cut or grind the joints. Such flexibility cuts down on work time. It also keeps the door function steady, even after long periods of service.

Exploring Self Closing Weld On Hinges for Secure Entry Systems

Functional Design of Self Closing Weld On Hinges

Self closing weld on hinges include a spring setup inside the main body. This built-in spring lets the door shut on its own after someone opens it. As such, the door goes back to closed no matter what the user does.

These hinges keep a steady closing power, even if the door weight changes a bit. That makes them a good pick for places that need tight control over doors without people having to push them shut every time.

Applications Where Self Closing Features Are Beneficial

Security-Focused Installations

People often use self closing weld on hinges in tight-security zones like locked labs, and limited-entry areas. Because these hinges make sure doors shut automatically in spots with gates or controlled access.

Safety Compliance in Commercial Settings

Business buildings must comply with fire regulations and work safety standards, often requiring self-closing fire-rated doors. Self closing weld on hinges help meet those fire code needs for doors that shut without help.

Convenience in High-Traffic Areas

These hinges operate in public areas including schools and medical facilities and retail stores to reduce the requirement for manual door closure. The door hinge system performs a reset operation which enables users to close the door after each use for better accessibility. The system maintains both security and building protection through its operation.

Comparing Weld-On Hinges With Traditional Bolt-On Alternatives

Structural Differences Between Welded and Bolted Hinges

The welded hinges create a seamless connection between the main structure and the hinge system. The hinges connect directly to the frame structure which enhances stability and produces exceptional strength. Bolted hinges function through screws or bolts which might lose their tightness because of pressure buildup that occurs when structures experience shakes or load variations.

| Feature | Weld-On Hinges | Bolt-On Hinges |

|---|---|---|

| Installation | Requires welding equipment | Requires drilling and fastening |

| Rigidity | High | Moderate |

| Maintenance | Low | May require re-tightening |

| Replacement | Difficult | Easy |

| Tamper Resistance | High | Moderate |

Performance Considerations Based on Installation Type

When to Choose Weld-On Options:

For setups that last forever and need real strength, like steel gates, weld-on hinges stand out. Their solid build makes them the best option.

When Bolt-On May Be Preferred:

In short-term jobs or cases where you might swap hinges later, bolt-on types give more room to move. This kind of hinge allows quick take-apart if needed.

Factors to Consider Before Welding Hinges on a Door Frame

Material Compatibility Between Hinge and Door Frame Metals

You must check if the metals match before you weld. Joining different metals, say aluminum to steel, calls for special steps or added materials to avoid weak spots or rust buildup.

STRZ provides tailored hinge options that fit exact material needs. This helps ensure the best results.

Access to Proper Welding Equipment and Skills Required

You need the right gear, like MIG or stick welders. Those tools suit different hinge thicknesses and metal types. Without solid welding know-how, you risk poor alignment or fragile connections.

Planning Hinge Placement for Proper Swing Clearance and Alignment

Wrong spots for hinges can cause problems later. Bad placement might lead to sticking, drooping, or doors that won’t open fully. STRZ’s support team offers guides to place them correctly, ensuring smooth functionality and long-term durability for your doors and panels.

FAQ

Q: Can a door hinge be welded directly onto any metal surface?

A: Yes, but compatibility between the hinge material and the door frame metal must be ensured. The welding process of different metals needs specific electrodes and filler materials which are designed for this purpose.

Q: Are adjustable weld on gate hinges available in different sizes?

A: Yes. STRZ offers various dimensions and also supports customized sizes tailored to your project requirements.

Q: Do self closing weld on hinges require regular maintenance?

A: No. The integrated spring mechanisms are sealed within the hinge body and designed for long-term use with minimal maintenance.

Q: How do I ensure proper alignment during installation?

A: Use adjustable weld-on gate hinges from STRZ, which allow for post-weld adjustments both vertically and horizontally.

Q: Can STRZ provide customized equipment for unique installation needs?

A: Absolutely. STRZ specializes in customized solutions, including hinge sizing, material selection, and surface treatments based on project-specific requirements.