Why Above Ground Post Systems Work Well with Metal Fence Posts

Understanding Above Ground Post Systems

What Defines an Above Ground Post System

Above ground post systems get rid of the need for usual concrete footings,which rely on surface-mounted or driven foundations like brackets or ground screws. Rather than digging deep holes and pouring cement, these setups hold structural posts above the soil line. As a result, they become flexible, removable, and less disruptive.

Common Applications of Above Ground Installations

Such systems often appear in uses like fencing, decking, small outbuildings, pergolas, and other light structures. Since these systems install without much digging or waiting for drying, they suit temporary or semi-permanent jobs well.

Above ground post systems work best in spots with bad drainage or frost heave issues. In those places, standard in-ground concrete footings tend to shift or break down over time. However, an above ground post backed by a ground screw stays firm and untouched by freeze-thaw cycles.

Advantages of Using Metal Fence Posts in Above Ground Systems

Durability and Strength of Metal Fence Posts

Metal fence posts provide better protection against rot, decay, and insect harm than wooden options. These posts keep their shape under heavy loads or strong winds. This matters a lot for fencing that faces weather forces.

Most metal posts come with protective layers such as hot-dip galvanization or powder coating. These galvanized layers create a thick shield, effectively fighting off rust, water, and chemical wear. Thus, these layers fit outdoor tasks perfectly. Even in tough conditions, they last over 10–15 years.

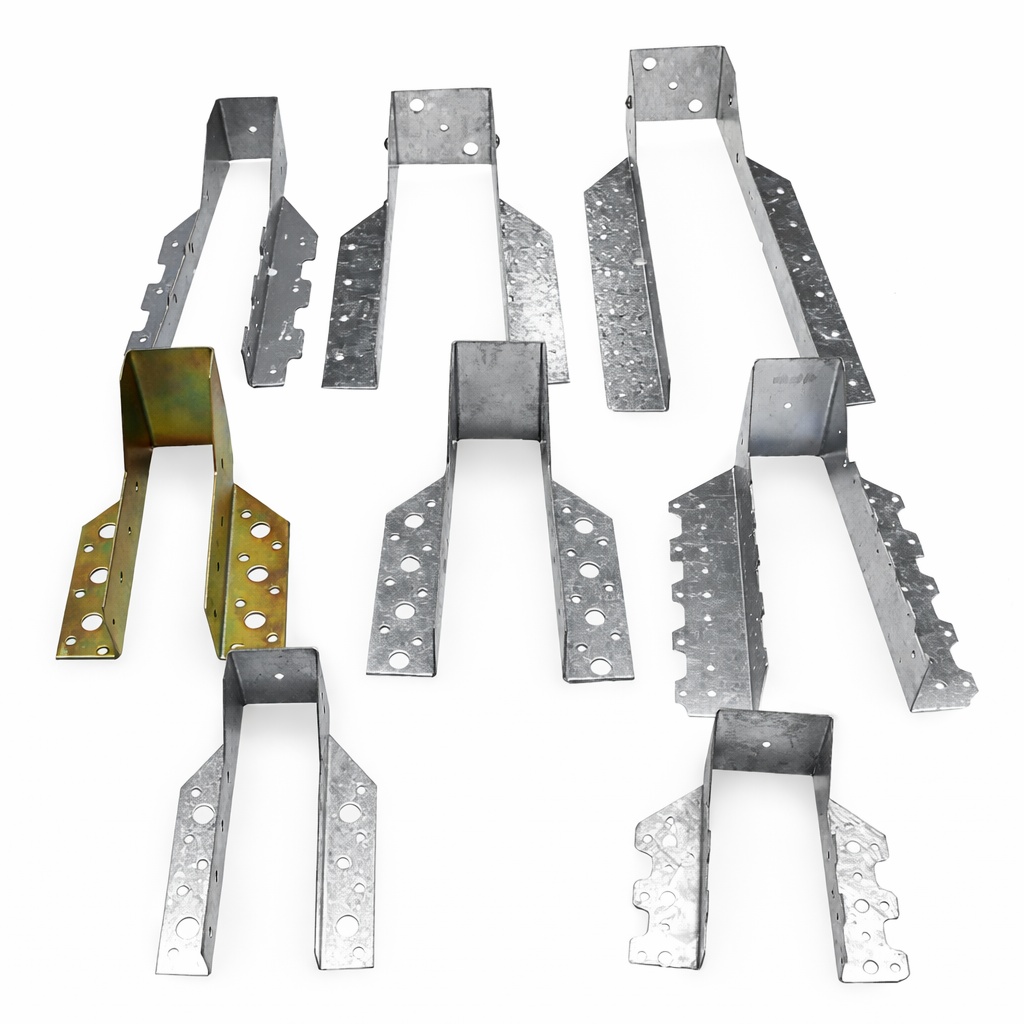

Compatibility with Mounting Hardware and Brackets

Standardized post dimensions allow metal posts to align easily with common brackets and connectors. Precisely positioned holes and consistent sizing simplify installation and ensure stable, accurate fastening in structural assemblies.

Lightweight Yet Structurally Sound Design

Despite their strength, metal posts are generally lighter than timber or concrete alternatives. This reduced weight simplifies transportation and on-site handling, helping lower labor effort and installation time while still providing reliable structural support.

The Role of Fence Post Ground Screws in Above Ground Systems

How Ground Screws for Fence Posts Work

Ground screws for fence posts act as a fresh substitute for concrete footings. Workers drive them into the soil to form a solid base without digging. These posts include helical threads that grip firmly into various soil types. Plus, these items allow for height tweaks after setup.

Benefits of Pairing Metal Posts with Ground Screws

-

Enhanced Installation Efficiency

The fast setup process shortens project schedules a great deal. For example, DIY garden room builds in Europe finish in just hours. They use STRZ’s tailored U-shape ground screws with penetration galvanizing, such as the U10x70x3.75×135 series.

-

Long-Term Stability and Adjustability

When metal fence posts sit on STRZ’s ground screws, like the M68x120x1000 M12 HDG, this kind of post shows little shifting. This holds true even in shaky soils or through seasonal shifts. The metal posts fight off motion from weather factors when held by ground screws. Therefore, the setups deliver lasting dependability.

-

Sustainability and Reusability Factors

Both metal posts and ground screws pull out and are reused in later projects. This cuts down waste. Their lower environmental harm compared to concrete setups fits green aims nicely. Such aspects prove vital in European markets.

Performance Considerations in Various Environments

Suitability for Different Soil Types and Climates

Ground screws show strong results in clay, sand, and rocky soils. When set up right, ground screws handle clay, sandy, or rocky soils well. This flexibility turns them into a practical pick across different areas.

Resistance to Moisture and Corrosion Over Time

-

Protective Coatings on Metal Posts

Zinc galvanization stops rust from forming in damp settings. Meanwhile, powder-coated layers resist UV rays to keep their looks intact long-term. STRZ’s penetration galvanizing reaches salt spray resistance beyond 400 hours. It suits adjustable connectors for outside use.

-

Drainage Benefits of Above Ground Designs

Raising above the soil line limits water touch at the post base. This lessens rot failures that often hit buried wood posts. The trait boosts the toughness of T-posts and fencing parts further.

Practical Use Cases for Above Ground Metal Post Systems with Ground Screws

Residential Fencing Projects

T-Posts and galvanized fence anchors suit privacy fences, dog enclosures, and decorative borders. Their pre-punched holes speed up and secure attachments. Protective layers ensure these posts last in any weather.

Commercial and Agricultural Applications

Jobs like farm perimeter fencing and industrial lot enclosures gain from quick rollout. They use sturdy U-shape fence post ground screws, such as 101×1300×1.8 mm models. These setups back strong metal posts in high wind or load situations.

Temporary Installations and Event Setups

From sports events to modular garden rooms, ground screws allow “install-use-remove” ease. No permanent harm comes to the land. Thus, these options fit rental gear or seasonal setups perfectly.

Key Takeaways When Choosing an Above Ground Post System with Metal Components

Factors to Evaluate Before Installation

-

Site Conditions

Before picking a ground screw type like M120x6/6x1200x1.8 mm, check soil firmness, slope angle, and drainage features. Tailored screw lengths and widths are available to fit certain lands.

-

Load Requirements

Make sure post wall thickness and screw depth match planned load needs. This proves key for wind-open builds. STRZ shares testing papers per ASTM rules upon request.

-

Aesthetic Preferences

Pick from powder-coated or galvanized options based on style goals. STRZ also gives custom coating work for colour fits or high-wear spots like shore areas.

Maintenance Expectations Over Time

-

Inspection Routines

Check often for corrosion signs at connection spots and ensure bracket firmness. Apply anti-corrosion grease on screw threads if required.

-

Replacement Planning

If a part breaks from chance harm or use over time, the modular style lets single pieces like posts or screws swap out. This avoids a full system pull without hassle, which saves effort and money.

STRZ offers engineered metal posts, ground screws, and connectors designed for fast installation and long-term stability. Contact STRZ to discuss project-specific requirements, customization options, and technical support for residential, commercial, or temporary installations.

FAQ

Q: Are metal fence posts better than wood for above ground systems?

A: Yes. Metal fence posts stand up much better to water, bugs, and rot than wood. Paired with the right layers like hot-dip galvanizing or powder coating from STRZ, they bring top-notch lasting power and steadiness.

Q: Can I install fence post ground screws myself?

A: Absolutely. STRZ gives setup guides fit for DIY folks. Many types, like the U10x70x3.75×135, work with hand tools or basic machines, even without past know-how.

Q: What types of soil can support ground screws?

A: Well-made ground screws fit clay, sandy, rocky, or sloped soils. STRZ supplies custom choices matched to exact soil setups for solid hold.

Q: Do metal posts require regular maintenance?

A: Little upkeep is needed if set up right. Normal checks for rust at bolt spots and now-and-then cleaning usually do the trick.

Q: Can I customize the size or finish of STRZ’s metal components?

A: Yes. STRZ handles size tweaks, coating tweaks, and role tweaks based on project wants. This serves both business and home users looking for fitted answers.