How Wood Connectors Improve Strength in Timber Structures

Understanding Wood Connectors in Timber Construction

Definition and Function of Wood Connectors

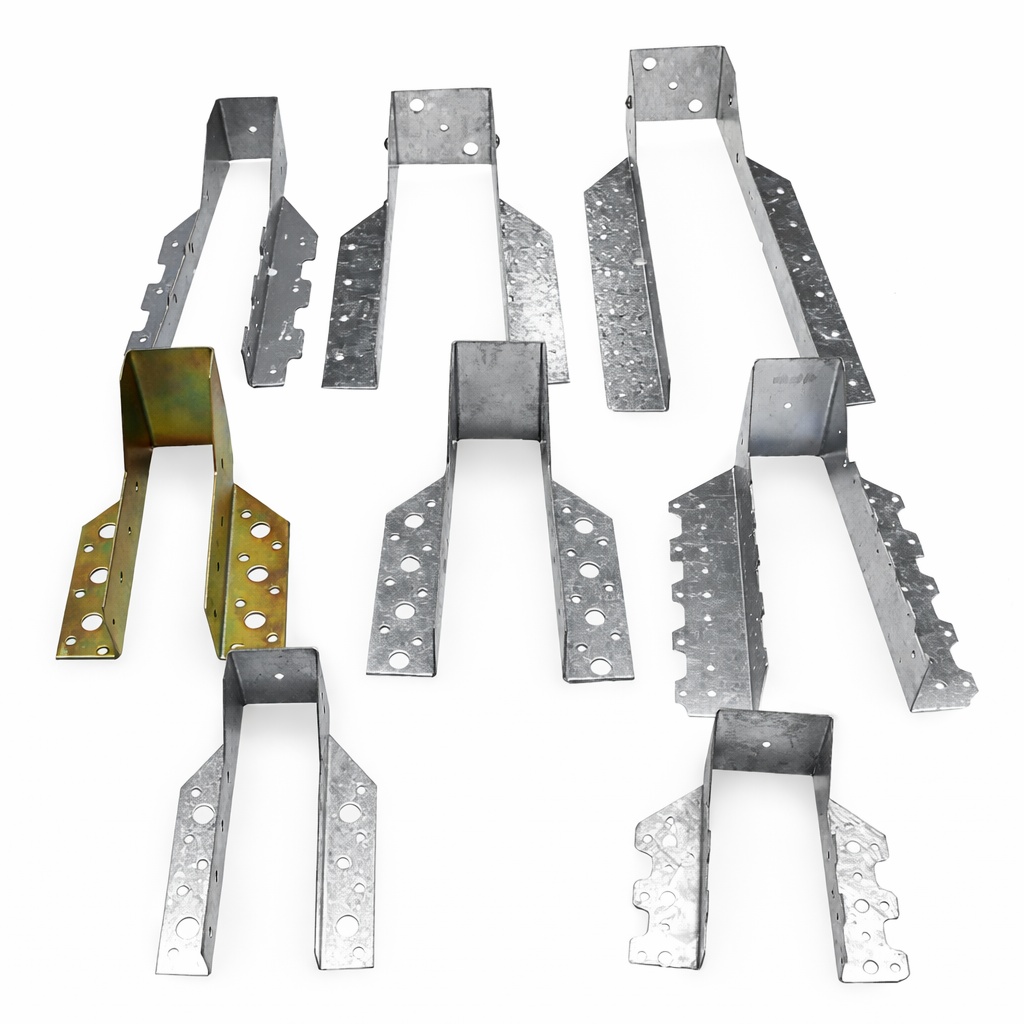

Wood connectors serve as key hardware pieces in timber building projects. These connectors firmly link wooden parts like beams, joists, posts, and rafters. Galvanized Wooden Connectors consist of top-notch steel items treated via hot-dip galvanization or electro-galvanization. These items aim to strengthen and fasten links between wooden parts, such as joists, rafters, beams, and posts. These connectors work well in building tasks and furniture making. This setup provides solid stability and lasting strength over time.

Such connectors spread out loads over the joint areas. As a result, they cut down on focused stress and boost the overall strength of the structure. Builders often make them from galvanized steel or stainless steel. These materials give strong protection against rust and wear in different weather settings. The galvanized layer creates a thick shield that fights off rust, dampness, and chemical damage well. Thus, these layers are suitable for use inside buildings or outside in the elements.

Importance of Structural Connections in Timber Design

In timber buildings, strong joints play a vital role. Well-chosen and correctly placed wood joint connector makes sure loads move smoothly between building parts. These connectors handle forces like pulling, sliding, and pressing. In turn, these connectors stop joints from breaking, guarding against failure from tension, shear, or compression. Besides, the connectors add a lot to the safety and long life of structures. This happens by steadying links that could wear down as years pass.

Types of Wood Joint Connectors and Their Applications

Mechanical Fasteners Used in Timber Joints

Simple mechanical fasteners like nails, screws, and bolts often appear in timber links. These items offer basic holding power at first. However, their success relies a great deal on how they are spaced, positioned, and combined with extra hardware such as angle brackets or joist hangers. Set hole spots and exact sizes, make sure these spots line up easily with wooden parts. This setup makes putting them in simpler.

Items like ST50082 strip nails (25×1.4 brass latent head) and galvanized wood screws (M4×25mm, M5×35mm) usually go with these connectors. These items help create a firm hold.

Metal Plate Connectors for Enhanced Stability

Metal plate connectors give better support by expanding the touching surface in joints. Split ring and shear plate connectors go into the wood to improve resistance to sliding forces. Tooth plate connectors also fight slipping strongly by holding onto wood fibers tightly. A broad range of options is available, including products such as the ST7047 flat connector (40×160×2.0 mm) and the ST7322 angle connector (40×40×40×2.0 mm). These connectors are well suited for truss systems and robust timber construction where reliable load transfer and joint stability are required.

Round Wood Connectors: Design and Usage

Round wood connectors act as round metal pieces fitted into cut grooves in wooden parts, boosting the ability to carry loads by increasing contact areas. These connectors show up often in log homes, post-and-beam setups, and planned wood groups. People like them for their hidden look and solid power. A good case is the ST7485 round pin (50/17×1.0 Zn). It has a small shape with smart load sharing.

Structural Benefits of Using Wood Connectors

Improved Load Distribution Across Timber Joints

Wood connectors aid in sharing building forces evenly over the joint space. These connectors spread forces smoothly across the joint surface. This action lowers stress buildups that might cause breaks or weak spots in one area.

Enhanced Resistance to Shear and Tension Forces

STRZ connectors use fine-quality steel with careful design. Because of this, they handle changing loads without bending. The connectors, built from high-grade steel, show great load-holding power and strike resistance, and meet tough safety rules for structures.

Increased Durability and Lifespan of Structures

Coatings that resist rust, like hot-dip or electro-galvanizing, ensure long-lasting use. These galvanized connectors outlast plain uncoated steel ones by 10–15 years in outside settings. Such extra time means less need for regular fixes or swaps.

Factors Influencing Connector Selection in Timber Structures

| Factor | Description |

|---|---|

| Load Requirements | Chosen based on axial, shear, or moment demands |

| Timber Species | Denser woods may require pre-drilling |

| Moisture Content | Affects wood movement around connectors |

| Environmental Conditions | Outdoor use demands hot-dip galvanized steel |

| Fire Resistance | Specialty connectors required for rated structures |

For high-density hardwoods (such as teak), it is recommended to pre-drill holes to prevent wood cracking.

Installation Techniques for Optimal Performance of Wood Joint Connectors

Precision Cutting and Pre-drilling Practices

Exact cutting makes sure fitted connectors, like round pins or split rings, sit snugly in their slots. Pre-drilling stops wood from splitting when adding screws or bolts.

Proper Alignment and Fastening Procedures

Good alignment matters a lot. If hardware is installed incorrectly, it weakens the whole structure. We supplies clear guides and torque details. These help with precise setup.

Common Applications of Round Wood Connectors in Modern Construction

Use in Log Home Construction

Round wood connectors give a neat appearance since they hide inside joints. This improves the visual appeal. At the same time, it secures tight links between logs.

Integration in Post-and-Beam Framing Systems

Round connectors such as ST74807 (50x50x35x2.0mm) enable ready-made beam groups. These connectors cause little visual break. This makes them perfect for business wooden spaces or open public areas.

Advantages of Using Engineered Wood Connector Systems

Modular Assembly for Faster Construction Times

Installers do not need to add rust protection during setup. As a result, this cuts building time and upkeep costs by 30%. Such savings help speed up projects. It proves especially useful in large housing or business developments. The use of a wood joint connector further enhances the modular approach, simplifying assembly.

Compatibility with Sustainable Building Practices

Our hardware fits smoothly with green timber methods like CLT or glulam. It backs the use of renewable items like glulam or CLT (cross-laminated timber). Tailored tool choices also improve how materials get used.

Maintenance Considerations for Long-Term Performance

Inspecting Connector Integrity Over Time

Checking regularly stands as a must. It spots early hints of rust or loose spots. This way, bigger problems get avoided before they harm the structure.

Protective Coatings and Treatments for Longevity

Zinc layers hold up against rust in wet places. If scratches happen during setup, we offers repair sprays with galvanizing and lubes against corrosion. These keep the hardware working well.

FAQ

Q: What’s the difference between hot-dip galvanized and electro-galvanized wood connectors?

A: Hot-dip galvanized connectors have a thicker coating (60–85μm) and stronger corrosion resistance, suitable for outdoor long-term use. Electro-galvanized connectors have a thinner coating (8–15μm) and are more cost-effective, suitable for indoor dry environments.

Q: Can STRZ wood joint connectors be customized for specific timber sizes?

A: Yes. STRZ offers dimension customization: adjust the length, width, and hole positions of connectors according to the customer’s wooden member dimensions.

Q: Are these connectors suitable for all timber species?

A: They are compatible with most common woods, including pine, oak, birch, and cedar. For high-density hardwoods (such as teak), it is recommended to pre-drill holes to prevent wood cracking.

Q: How long do galvanized STRZ connectors last in outdoor applications?

A: Compared with ordinary uncoated steel connectors, they have a 10–15 year longer service life in outdoor environments.

Q: Do STRZ connectors comply with international building codes?

A: Compliant with international building codes (such as ASTM, DIN), ensuring compatibility with global wooden structure projects.