How to Choose Stainless Timber Connectors for Long-Lasting Structures

Why Stainless Timber Connectors Are Essential for Durable Timber Structures

What Makes Stainless Steel Ideal for Timber Connections

Stainless timber connectors serve a key function in today’s building projects. These components are especially useful in places that need both solid strength and lasting endurance. A major benefit of stainless steel lies in its strong ability to fight off rust. This quality helps ensure long life in open-air and damp settings. As a result, stainless steel timber connectors work well for buildings facing water, like seaside houses, patios, or garden shelters.

Stainless steel brings a good balance of power and lightness. It delivers firm backing without making the build too heavy. This matters a lot when handling big wooden beams or cross-laminated timber (CLT) in mass timber connections.

Furthermore, stainless steel pairs nicely with wood. It lowers the chance of bad reactions that might cause marks or breakdown of materials as years pass. Such features position stainless steel as a top choice for jobs that call for good function and nice looks.

How Stainless Timber Connectors Improve Structural Performance

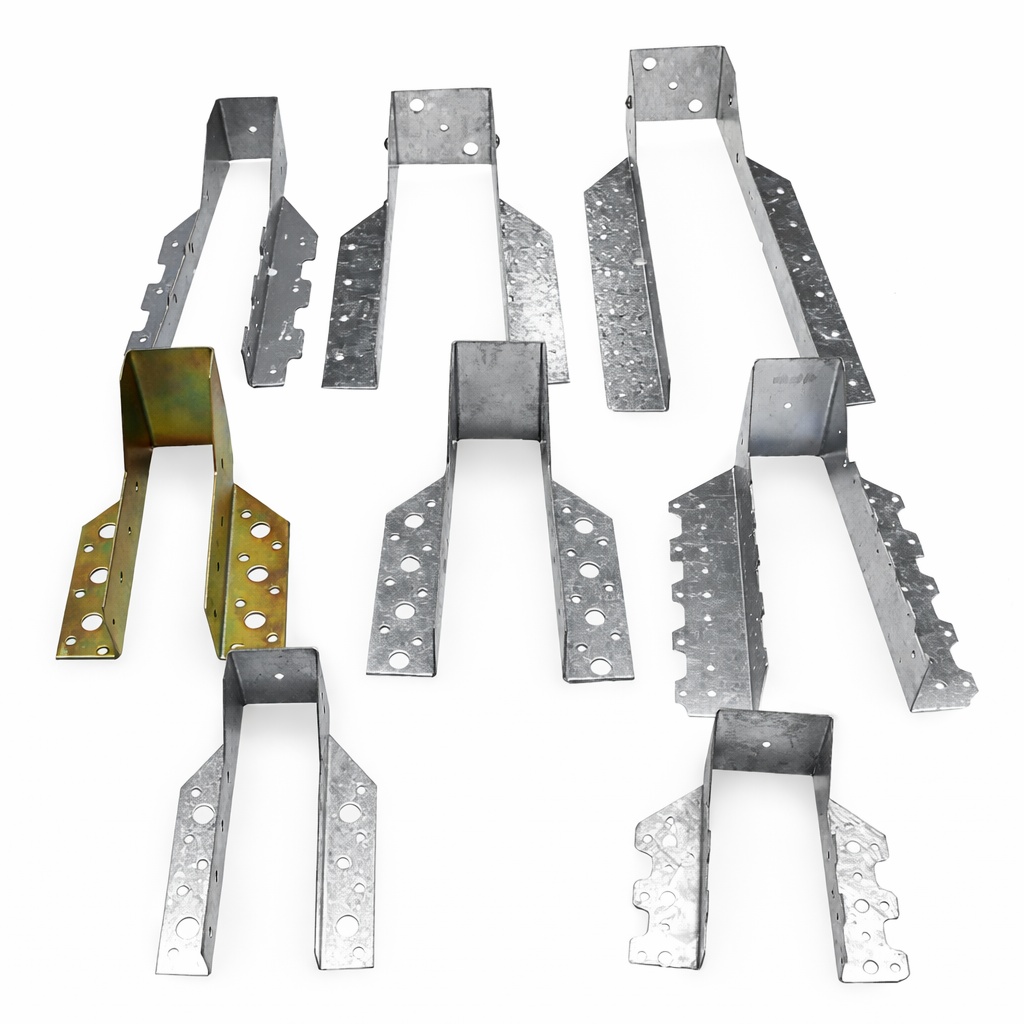

Stainless steel timber connectors are built to spread out forces smoothly over wooden joints. These connectors help avoid spots of heavy pressure that could cause breaks or breakdowns. For example, STRZ’s connectors, including joist hangers, beam brackets, and angle plates, come from top-quality steel. This setup boosts how much weight they hold and keeps things steady for a long time.

These items also cut down on shifting and bending as time goes on. That proves vital in uses like home roof frames or business outdoor platforms.

For big projects such as mass timber connections, the connectors boost the whole building’s safety, doing this by offering dependable joint support. This adds a lot to the firmness of tall wooden buildings and roof setups. These face-changing forces, like gusts of wind or earthquakes.

How to Identify the Right Type of Stainless Steel for Timber Connectors

Understanding Different Grades of Stainless Steel

Every type of stainless steel does not provide equal defense against wear. Grade 304 suits everyday inside jobs with little contact with harmful elements. On the other hand, Grade 316 has molybdenum added. This gives it better guard against salts, so people pick it for beachside, water-related, or wet spots.

Factors That Affect the Choice of Stainless Steel Grade

A few things shape the pick of stainless steel grade for timber connectors:

-

Environmental Exposure: Lots of dampness, salty breezes, and harsh chemicals call for better stainless steel.

-

Load-Bearing Requirements: Bigger or trickier builds might need thicker or tougher connectors.

-

Budget vs Longevity: Grade 316 costs more at first, but it saves money later. That’s because it needs less upkeep and lasts longer.

Additionally, STRZ also provides galvanized alternatives—hot-dip galvanized (60–85 μm) and electro-galvanized (8–15 μm)—for projects balancing cost and corrosion protection .

What Types of Stainless Timber Connectors Are Commonly Used in Construction

Overview of Common Connector Types and Their Applications

| Connector Type | Application |

| Joist Hangers | Provide strong support at beam-to-joist intersections |

| Beam Brackets | Secure horizontal beams at junctions |

| Post Bases & Column Shoes | Anchor vertical timber posts to concrete or ground-level footings |

| Truss Plates & Gussets | Reinforce angled joints in roof trusses or diagonal bracing |

How Each Connector Type Supports Different Timber Designs

Builders can find these connectors in many forms and measurements to fit various building styles. Custom setups give room for changes in mass timber plans. This holds true for bent beams, overhanging patios, or open roof frames.

Most stainless steel timber connectors come pre-planned with set hole layouts and sizes. Such designs make setup easier and lower worker time and costs. Setting hole spots and exact sizes helps line up well with wood parts, which makes the whole process smoother.

How to Choose the Right Stainless Timber Connector for Your Project Needs

Evaluating Load Requirements and Structural Demands

Picking a connector starts with checking the kinds of forces, like pulling, sliding, and twisting, that each joint must handle. Engineers should run math checks or stick to rules-based product details. This way, the picked connectors match the building’s needs.

Considering Environmental Conditions and Longevity Goals

Outdoor patios, shelters, or water-adjacent builds demand stainless timber connectors. Their rust-fighting trait stretches the platform’s useful time to 15 years. That’s double what plain connectors offer.

Teams can add special layers based on the surroundings. For instance, boost the zinc coating up to 100μm in spots with heavy rust risks, like near the ocean.

Matching Connector Design with Aesthetic Requirements

Visible wood builds care about how things look. Stainless steel’s smooth style can get better with added touches like powder layers or old-style brass shades. Plus, brands like STRZ supply hidden connectors. These fit clean, simple designs.

Why Proper Installation of Stainless Steel Timber Connectors Matters

Best Practices for Installing Stainless Connectors in Wood Structures

Good setup greatly shapes how well things work. Drilling holes ahead of time stops wood from cracking, above all in tough woods or dry pieces. Screws and bolts need to match stainless steel to skip metal-on-metal rust.

To dodge metal reaction rust, pair similar metals. For example, skip mixing stainless steel connectors with zinc-covered bolts.

Common Mistakes That Compromise Connector Performance

-

Pairing wrong metals, such as zinc screws with stainless connectors, speeds up rust.

-

Tightening screws too much can crush wood or create weak spots that harm the joint later.

What Role Do Stainless Timber Connectors Play in Mass Timber Construction

Supporting Large Spans and Heavy Loads Safely

Building with mass timber and CLT panels calls for connectors that handle tall-building weights. Stainless steel timber connectors allow wide reaches while keeping safety high.

These connectors hold the building’s strength steady during active events like quakes or big winds. This comes from reliable joint action.

Enhancing Fire Resistance and Code Compliance

Stainless connectors aid fire protection too, passing less heat than plain steel does. Thus, the connectors slow warmth spread in blazes and help meet rules for open connector setups.

How to Maintain Structures Built with Stainless Steel Timber Connectors

Periodic Inspection Guidelines for Long-Term Durability

Annual inspections need to evaluate connector status and screw tightness and search for rust signs and wood foundation movement that causes joint looseness. Replace damaged components immediately to prevent additional damage from occurring.

Cleaning and Protecting Exposed Stainless Components

Stick to gentle cleaners for upkeep. Keep connectors away from salt-heavy items like swimming pool mixes or road salt. Those can pit the surface after a while.

FAQ

Q: What grade of stainless steel is best for outdoor timber projects near the sea?

A: Grade 316 is recommended because it offers superior resistance to salt and moisture exposure in marine environments.

Q: Can I use galvanized fasteners with stainless steel timber connectors?

A: No. Mixing metals can lead to galvanic corrosion; always use compatible stainless steel fasteners.

Q: Are there customized options for stainless timber connectors?

A: Yes. Provide enhanced galvanizationor color-coated galvanization for aesthetic needs. Customized dimensions and finishes are also available depending on project needs.

Q: What types of timber connectors are most commonly used?

A: Joist hangers, beam brackets, post bases, column shoes, gussets, and truss plates are widely used depending on the structural requirement.

Q: How long do stainless steel timber connectors last?

A: When properly installed and maintained, stainless steel connectors can last over 20 years even in harsh environments due to their superior corrosion resistance.