How a Connector for Wood Enhances Structural Timber Integrity

Understanding Wooden Connectors and Their Role in Wood Structures

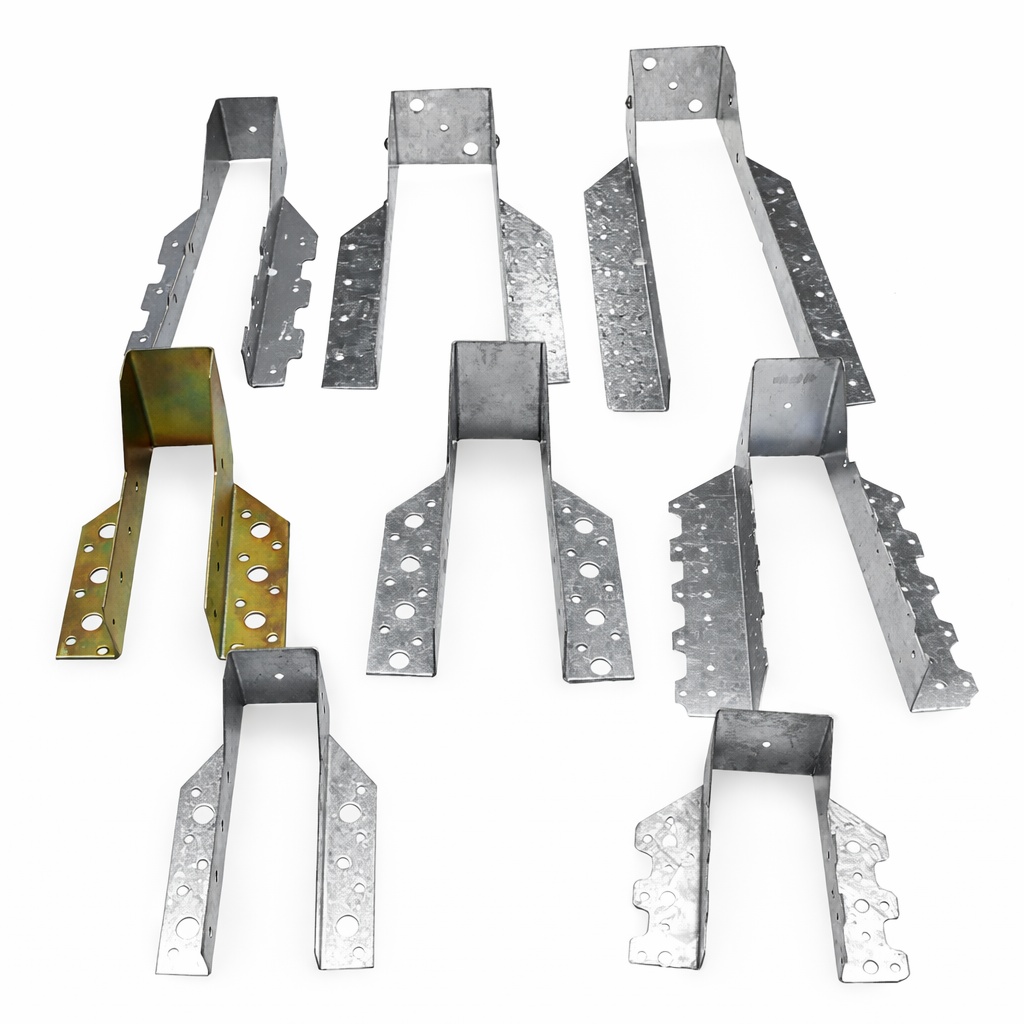

Wooden connectors play a vital part in today’s wood building projects. This connector for wood offers strong links between key wooden parts like beams, joists, rafters, and posts. These metal pieces boost the overall strength of wood setups. At the same time, they help make wood frames last much longer.

Galvanized Wooden Connectors consist of sturdy steel items treated with hot-dip galvanization or electro-galvanization. Builders use them to strengthen and fasten joints between wooden elements, including joists, rafters, beams, and posts. This applies to both building work and furniture making. Such connectors guarantee solid support and lasting strength. People choose them for indoor and outdoor spots because these connectors resist rust well and handle heavy weights effectively.

Types of Connectors for Wood and Their Applications

Common types of wood connectors

Wooden connectors appear in many shapes. Each one fits certain tasks. Here are some popular kinds:

| Connector Type | Application Area | Load Range (N) | Dimensions (Example) |

|---|---|---|---|

| Joist Hangers | Floor joists, deck framing | 800–1200 | ST14338: 40×94×2.0mm |

| Beam Hangers | Roof beams, ceiling frameworks | Up to 5000 | ST71003: 175×175×35×2mm |

| Angle Brackets | Furniture assembly, fence posts | Varies by model | ST8604: 20×20×15×2mm |

| Flat Connectors | Wall framing, shelf supports | Moderate loads | ST7047: 40×160×2.0mm |

| Rafter Ties | Roof truss reinforcement | High-load areas | Customized on request |

A Joist Hanger serves as a galvanized wooden connector built to hold up floor joists. It stops joists from twisting. Plus, it makes sure loads pass along steadily.

Builders can opt for tailored options like better galvanization or size changes to match particular job demands. This proves helpful in places near the sea or for special building styles.

Common Uses: Wood Fence and Railing Connectors

Wood fence connectors and wood railing connectors hold an important spot in home yard work and safety setups. Common tasks include:

-

Fastening rails to fence posts with angle brackets or T-shaped connectors for a firm hold.

-

Strengthening edges using L-shaped brackets like ST5005 (30×30×15×1.5mm).

-

Adding nice looks and guard features with decorative post caps from STRZ.

For yard projects such as garden trellises or walkway paths in scenic areas, galvanized connectors work great. Their rust-proof nature and ability to withstand weather make them perfect.

How Wooden Connectors Enhance Structural Integrity in Timber Construction

Connectors mainly work to keep wooden parts in line, and help spread out loads in a smart way. Crafted from top-notch steel, these items show great strength for carrying weight, resisting hits well too. Moreover, they follow tough rules for building safety.

For instance, install galvanized rafter ties and beam hangers to join rafters with beams. This setup improves how well a roof stands up to wind and snow pressure. Tests in spots with lots of snow confirm this approach. It cuts down roof breakdowns by 60%.

What’s more, the standard spots for holes aid exact placement. As a result, setup mistakes drop. Stress on wood faces stays even too.

Key Factors to Consider When Choosing Wood Connectors

Pick the best connector by looking at a few main points for your setup:

-

Material Type: Q235 Steel (hot-dip galvanized), 304 Stainless Steel (electro-galvanized), or DX51D+Z275 galvanized sheet/plate/steel.

-

Corrosion Resistance: Hot-dip galvanized connectors feature a thicker layer (60–85μm). This gives better protection against rust, suiting long outdoor use.

-

Load Requirements: Select according to planned pressure. Joist hangers usually handle 800–1200N.

-

Connector Size & Hole Pattern: Tailor hole sizes (often 4.5–6mm) to match M4–M5 screws.

-

Environmental Exposure: In salty sea air or very wet spots, ask for extra galvanization (up to 100μm thick).

Installation Techniques and Best Practices for Wooden Connectors

Proper setup brings out the full potential of these items. Here are some useful tips:

-

Use Appropriate Screws: Go with fitting galvanized wood screws (M4×25mm, M5×35mm).

-

Avoid Over-tightening: This stops bending in the connector or the wood.

-

Pre-drilling for Hardwoods: With dense woods like teak, drill holes first. This avoids splits in the material.

-

Protective Coatings: Apply galvanized repair spray to fix any scratches that happen while setting up.

-

Alignment Checks: Make sure parts sit flat before securing every screw.

Material Compatibility and Durability of Wooden Connectors

Long-lasting quality comes from the right materials and treatment process. The galvanized layer creates a tight shield. It fights off rust, dampness, and harsh chemicals quite well. Thus, these pieces fit wide temperature shifts from −40°C to 80°C.

On top of that, when compared to plain steel without coating, these items last 10–15 years longer in open-air conditions.

STRZ supplies items with special penetration galvanizing too. This makes threads smoother on parts that adjust. Such features help in pieces that need regular moves or takedowns.

Conclusion

Wooden connectors stand as key parts in wood buildings, improving how well structures perform. These connectors also support simple home projects with wood railing connectors or wood fence connectors. In short, these elements set the toughness and endurance of wood frames. STRZ delivers a full lineup of choices. This includes custom tools for size, coating, or special uses. All follow global rules like ASTM. So, for home roofs or pretty yard fences, solid wood links begin with good hardware.

FAQ

Q: What type of wooden connectors are best for outdoor fencing?

A: Hot-dip galvanized angle brackets or T-shaped brackets work well because they fight rust. STRZ’s ST7007 (40×40×15×1mm) ranks as a top pick.

Q: Can I use wood connectors on hardwoods like oak or teak?

A: Yes. Still, drill holes ahead to stop the wood from splitting.

Q: How do I know if the connector can support my structure’s weight?

A: Each batch comes with a test report. It follows ASTM D1761 standards. You might also check with outside testing groups.

Q: Do STRZ connectors require additional anti-corrosion treatment after installation?

A: No extra rust protection needs during setup. This cuts build time and upkeep costs by 30%.

Q: Can STRZ provide custom sizes or finishes?

A: Yes. STRZ handles size changes, coating tweaks (up to 100μm), and added features like shock pads or grip washers to fit job needs.